Production system

Development and Production System

We will quickly deliver stable quality and low-cost products to our customers

because our R&D department in the Philippines and Japan give us the advantage

of being able to integrate products from development to mass-production that meet customers’ requirements.

International quality standard: ISO 9001 certification

because our R&D department in the Philippines and Japan give us the advantage

of being able to integrate products from development to mass-production that meet customers’ requirements.

International quality standard: ISO 9001 certification

Introduction of production line (partial)

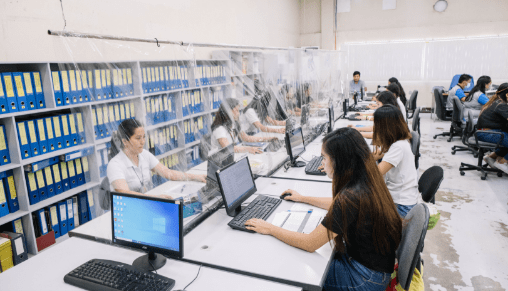

Production Control

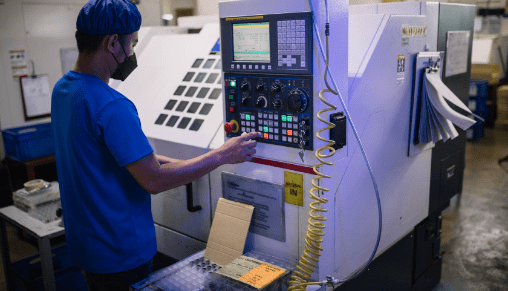

Cutting machine, keep a list of equipment

Equipment name

-

Brother CNC Machining Center

-

Brother CNC Tapping Center

-

CITIZEN Miyano NC Lathe

-

Kitamura NC Lathe

-

Knurling Machine

-

Vertical Milling Machining Center

-

Broaching Machine

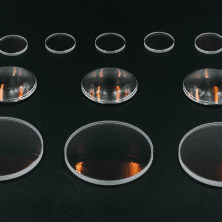

Lens Processing Equipment List

Equipment name

-

Pellet Polishing Machine

-

Curve Generator Machine

-

Pads Polishing Machine

-

Lens Centering Machine

-

Prism Polishing Machine

-

Prism Slot Cutter

-

Vertical Axis Surface Grinding Machine

-

Ultrasonic Washing Machine

-

UV Bond Drying Machine

-

Lens Coating Machine

-

Lens Dryer

Rifle Scope Production Line

Equipment Name

-

Collimator

-

Ultrasonic Washing Machine (single layer)

-

Ultrasonic Washing Machine (triple layers)

-

Soda Blasting Machine

-

Laser Marking Machine

-

Pad Printing Machine

-

Silk Screen Printing Machine

Binocular production line

Equipment Name

-

Collimator

-

Optical Axis Alignment Machine

-

Laser Marking Machine

-

Pad Printing Machine

-

Silk Screen Printing Machine

Injection molding, guaranteed equipment list

Equipment Name

Units

-

Nissei Plastic Industrial, Ltd. 40t3

-

Nissei Plastic Industrial, Ltd. 50t1

-

Haitian International Holdings 60t1

-

Nissei Plastic Industrial, Ltd. 60t1

-

Nissei Plastic Industrial, Ltd. 80t5

-

Nissei Plastic Industrial, Ltd. 110t1

-

Nissei Plastic Industrial, Ltd. 120t5

-

Haitian International Holdings 160t1

-

Nissei Plastic Industrial, Ltd. 180t2

-

Nissei Plastic Industrial, Ltd. 210t1

-

Sumitomo Heavy Industrial, Ltd. 220t1

-

Haitian International Holdings 250t1

-

Fanuc Corporation 30t (For Lens)1

-

Nissei Plastic Industrial, Ltd. 50t (For Lens)1

-

Sumitomo Heavy Industrial, Ltd. 120t (For lens)1

-

Spray Paint Booths2

-

Single Paint Booths10

-

Pad Printing Machine-

-

Hot Stamping Machine-

-

Silk Screen Printing Machine-

Production Control

Equipment name

Units

-

NC Lathe19

-

Tapping Machine9

-

General-purpose lathe4

-

General-purpose milling machine1