Production system

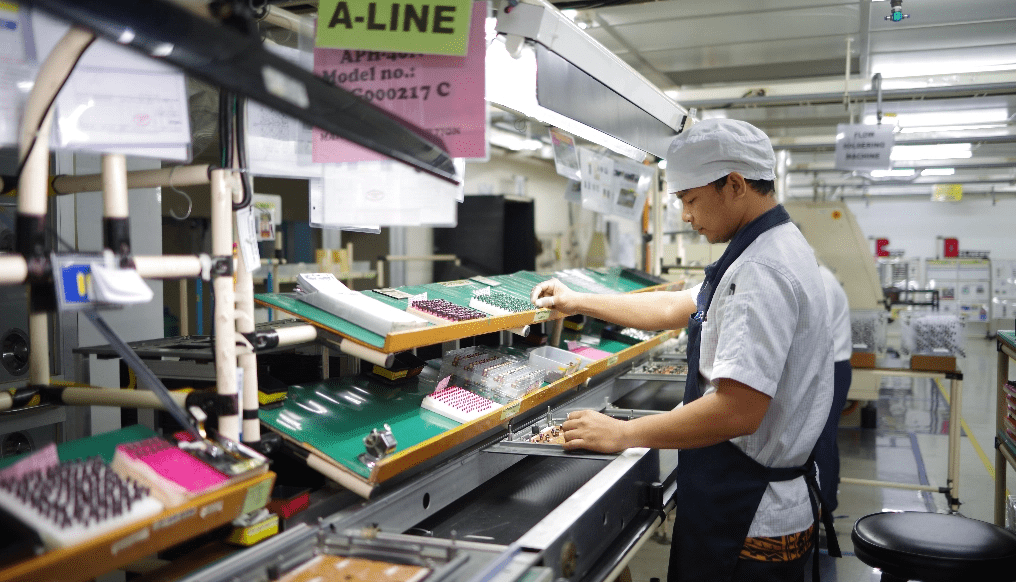

Development and Production System

We have development divisions in the Philippines and Japan. We will design the board and stencil mask.

We also purchase electronic parts and manage them with dry cabinets.

We also purchase electronic parts and manage them with dry cabinets.

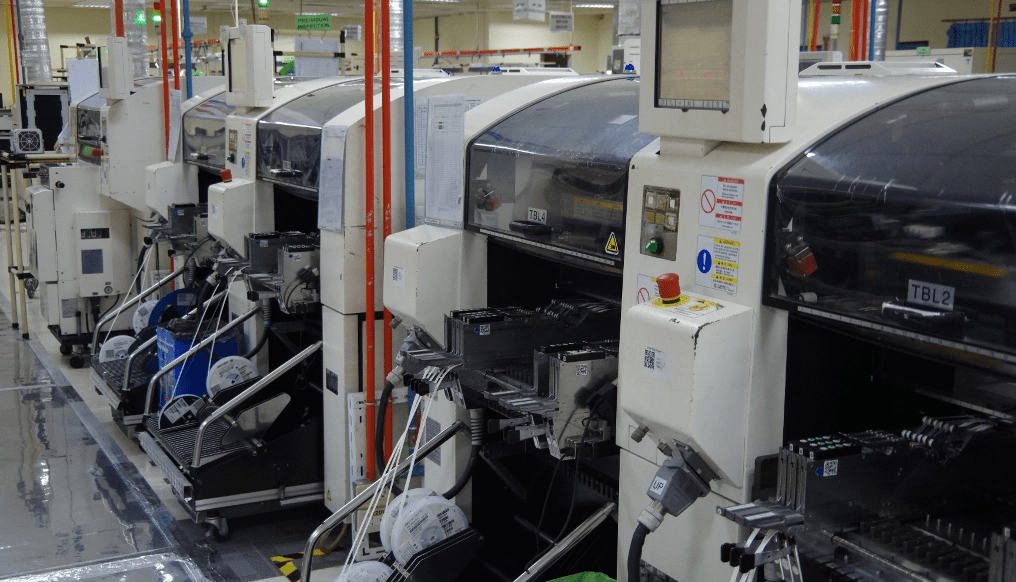

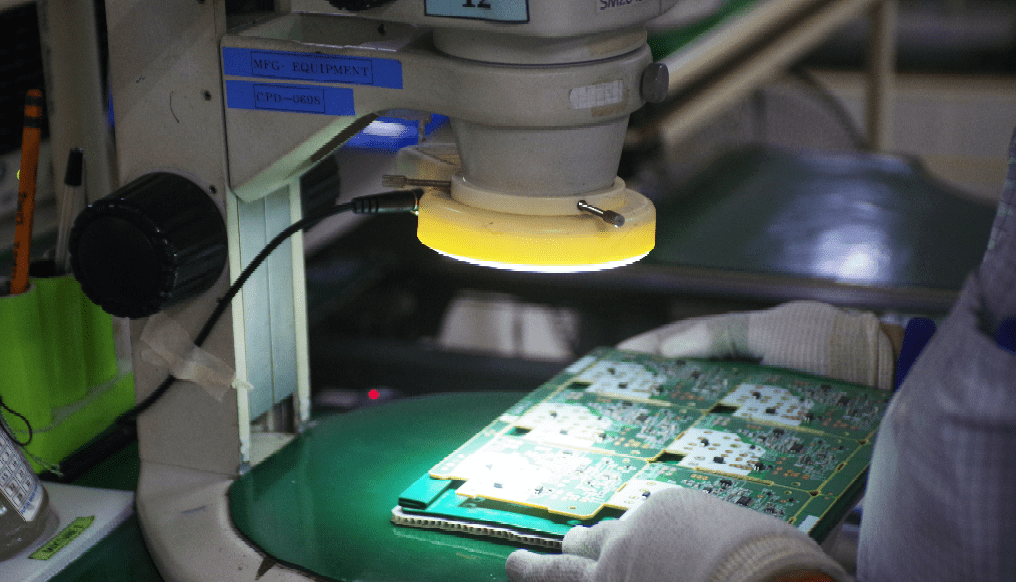

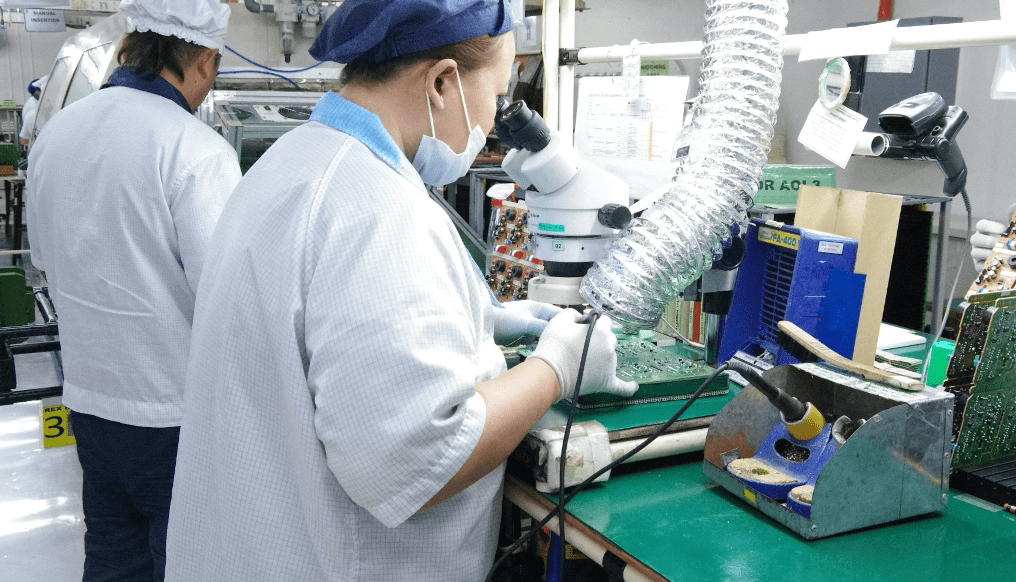

Introduction of production line (partial)

Soldering Iron

Surface Mount Device

Equipment Name

Units

-

Cream Solder Printer(SP60P-M)3

-

Cream Solder Printer Inspection System(BPC707AD)2

-

Cream Solder Printer Inspection System(TR7007i)1

-

Adhesive Dispensing Machine(NM-DC10)2

-

Chip Mounter(CM602)1

-

Chip Mounter(CM402-L)1

-

Chip Mounter(CM402-M)2

-

Chip Mounter(DT401)3

-

Chip Mounter(CM212)1

-

Chip Mounter(CM201)1

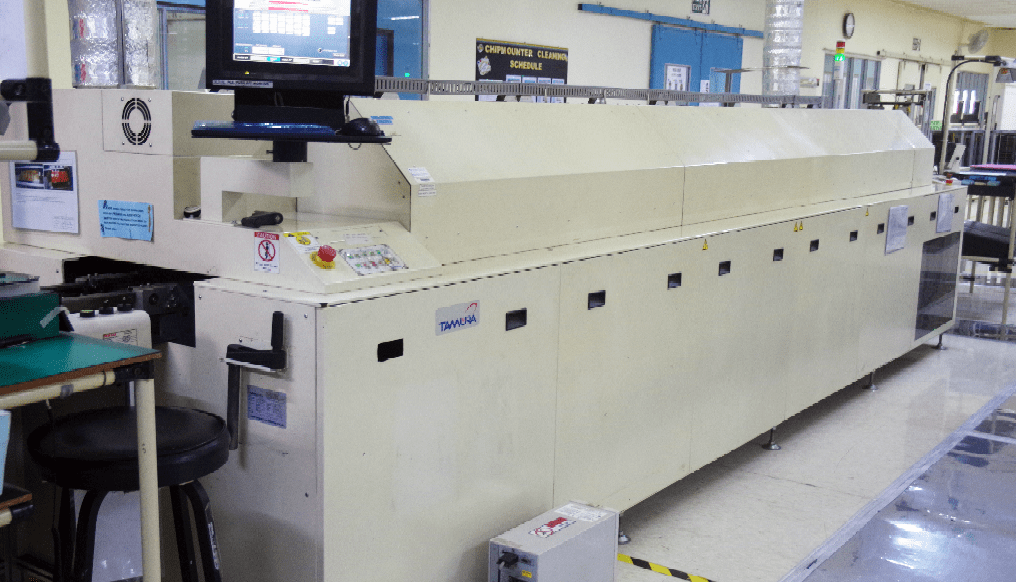

N2 Compatible Reflow

Equipment Name

Units

-

Reflow(TNP25-537ME)1

-

Reflow(TNV30-508EM-X)1

-

Reflow(TNP25-538EM)1

-

Reflow(TNP30-587PH)1

-

N2 Gas Generator(KN4-40SP)1

-

N2 Gas Generator(KN4-60SP)1